This website uses cookies so that we can provide you with the best user experience possible. Cookie information is stored in your browser and performs functions such as recognising you when you return to our website and helping our team to understand which sections of the website you find most interesting and useful.

CARGO HOLD CLEANING STANDARDS: HOLD WASHING, INSPECTION AND POLLUTION PREVENTION

Published: 2 January 2024

Ensuring cargo holds are cleaned to appropriate standards is an essential for shipowners operating bulk carriers. Failure to meet these standards can lead to cargo damage, noncompliance with regulations, pollution, and significant delays in operations, all of which can lead to claims. Understanding the hold cleanliness requirements is often instrumental when analysing major claims.

Typically, the Charterer establishes hold cleanliness requirements, which vary based on the previous cargo, the future cargo, local regulations, and any specific cargo interest requirements. For example, ships calling at Australian ports typically have more stringent regulations in terms of cleanliness, and a low biosecurity tolerance, particularly with grain cargoes. The International Maritime Solid Bulk Cargoes (IMSBC) Code also stipulates “hold cleanliness” requirements that must be followed when carrying cargoes listed within the Code. Cargo schedules mostly specify that special requirements are not required, or that the holds should be clean and dry in accordance with the cargo hazards. Others contain more specific advice, such as the entry for SULPHUR (formed, solid), which states that the hold should not be washed with seawater.

HOLD INSPECTIONS

Regular inspections and maintenance of the cargo hold should be conducted as part of a documented planned maintenance system within the Safety Management System (SMS). After every discharge and subsequent cleaning, holds should also be inspected by a responsible officer with any defects noted and repaired promptly. Typical areas of inspection include:

- Hold framing

- Structural access points (ladders, handrails etc.)

- Condition of hatch covers and all associated parts (trackways, hatch rubbers etc.)

- Paint coating condition

- Bilge system

- Light fittings

- Tank top areas

- Pipework within the hold

- Fixed firefighting systems

Managers should establish effective practices for cleaning areas that may be difficult to access or inspect, such as stiffeners under the deck in hold ends, which may require specialist equipment such as cherry pickers.

CLEANLINESS STANDARDS

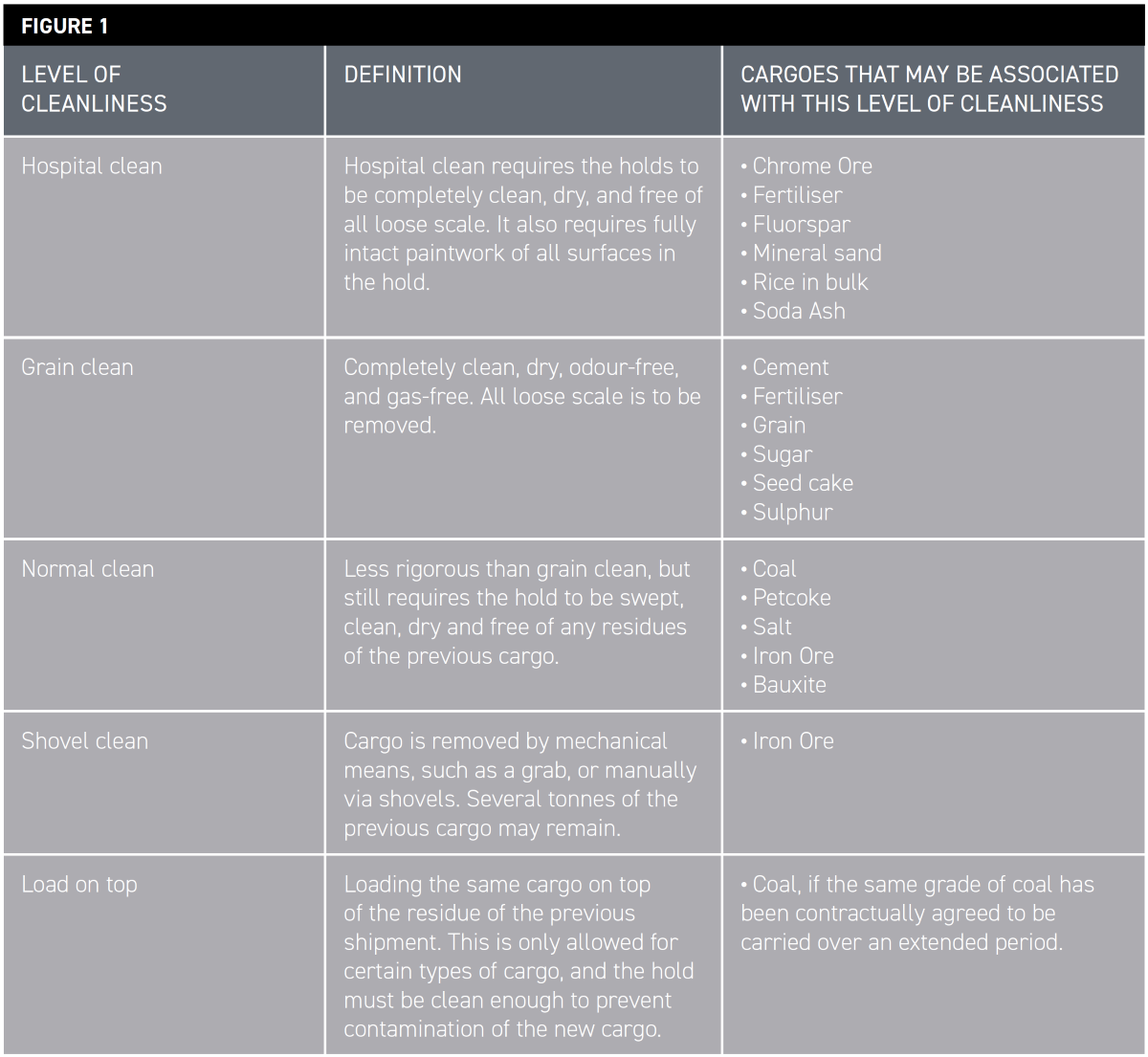

Figure 1 shows definitions of common industry standard cleanliness requirements, as well as cargoes that may be associated with the different levels of cleanliness. The cargoes listed are provided only as a reference and Charterer’s instructions and/or hold cleanliness standards listed within the IMSBC Code must be followed. Hospital clean is the highest cleanliness level and is normally only met by ships exclusively trading specific cargoes, with it rarely being seen in the tramp trades. Grain clean is the most common of requirements, particularly if the ship has not been fixed for the next cargo. It is worth noting that when cleaning to “load on top” standards, the remaining cargo residues will not facilitate a full inspection of the hold for any damages.

If the ship needs to be ‘swept clean’ before it is redelivered, then the stevedores at the discharge port should sweep the holds before completing the discharge to minimise any remaining residues. However, if the ship requires a ‘shovel clean’, the stevedores only need to discharge the cargo that can be easily accessed with a mechanical shovel. In such cases, several tonnes of cargo will still be left in each hold, which must be swept up and brought to the deck for disposal as permitted.

HOLD WASHING

It is crucial for the master to conduct a thorough risk assessment to ensure a safe hold cleaning operation. This includes assessing the use of chemicals during the washing-down process and providing accurate data (SDS) to the ship. Additionally, job-specific risk assessments, toolbox talks, and the proper use of personal protective equipment must be implemented. This ensures clear guidelines on the necessary cleanliness level including the absence of loose rust, bare steel, or fully painted and cured surfaces.

When cargo operations are paused, crew members may have the opportunity to access the upper areas of the cargo hold to brush and remove cargo. However, this should only be done with permission from the port authorities or berth operator, and after conducting a risk assessment to ensure safety and feasibility. It is recommended to start cleaning the hatch covers and surrounding areas on the deck before departure, once the hold is empty. It is important to consider the possibility of water entering adjacent holds through open hatch lids and to comply with local regulations regarding wash water and runoff. Some port states enforce strict requirements and impose fines and delays for non-compliance.

It is important to sweep out the coamings, drain channels and check the drains for debris before washing down the cargo holds. It is not recommended to use compressed air to remove debris from the channels and off the coamings. To ensure that all previous cargo residues and loose rust have been removed, it may be necessary to open and close the hatches a couple of times, if safe to do so. This migration of residues needs to be considered when washing holds while cargo remains in onboard in other holds, this may occur through adjacent areas to the hatches or via the cargo hold bilge system, which should be isolated during cleaning.

For efficient cleaning, begin by working from the top down during traditional water washing. When using chemicals, follow the manufacturers’ instructions, which may specify cleaning from the bottom to the top. Begin with the hatch covers and coamings, then move on to the underdeck area, bulkheads, upper hoppers, side shell plating, lower hoppers, tanktop, and finish with the bilges. It’s crucial to use cleaning chemicals that are compatible with the paint system in the holds and the upcoming cargo, some chemicals make it easier for cargo residues to stick to the hold surfaces. Additionally, verify that the hold coatings are suitable for the next cargo. If possible, using hot or warm water can facilitate the cleaning process and enhance the effectiveness of cleaning chemicals and detergents.

Consider the potential impact of cargo residues on fixed cargo hold bilge systems when pumping wash water overboard. The bilge system components, including pumps, valves, and eductors, may be affected by the nature, size, and abrasive properties of these residues, such as sands and cargoes containing fine particles.

Always ensure there is enough fresh water available for a final thorough rinse of all cargo holds to eliminate all chloride traces. Salt water residues can lead to a failed hold cleanliness inspection, pollute future cargoes either by direct contact or through dripping salt-laden sweat, and cause coating breakdown and corrosion. If chlorides are detected during silver nitrate tests of moisture in the hold, it can result in allegations of seawater ingress, complicating the defence of the ship’s position. Therefore, a complete fresh water rinse is crucial, and many bulk carriers carry large amounts of fresh water in the aft peak ballast tank for this purpose. This fresh water may originate from convenient locations, such as when transiting fresh water lakes, or the ship may gather water from air conditioning condensate. The fresh water wash should ideally be done before the holds dry, making it easier to remove salt residues. The fixed water lines will initially contain salt water, which should be flushed out with fresh water before the fresh water rinse.

In some cases, cargo interests or charterers may advise against a fresh water wash. Before loading, the holds and bilge wells should be completely dried. Opening the hatch covers, if safe and practicable, can aid in drying. Hatches opened while underway should be securely fastened with additional securing devices as needed. The use of mechanical ventilators, where available, can speed up the drying process.

POLLUTION PREVENTION

MARPOL (International Convention for the Prevention of Pollution from Ships) sets out guidelines for preventing pollution from ships. Annex V of MARPOL focuses on preventing pollution by garbage from ships, which specifically apply to the disposal of cargo residues and wash water into the marine environment. Crews should comply with the specific regulations related to cargo residues, including their disposal and cleaning requirements. These requirements state:

- No discharge of cargo residues should occur less than 12 nautical miles from the nearest land, or the nearest ice shelf

- No discharge of cargo residues should occur within the six MARPOL defined ‘Special Areas’ – Unless all conditions listed in MARPOL Annex V regulation 6.2 are fulfilled

- No discharge of any cargo residues specified as Harmful to the Marine Environment (HME)

- Hold wash water should be discharged to a suitable reception facility

It is essential to maintain accurate records of hold cleaning operations, including the date, time, cleaning method, and any chemicals used. These records will serve as evidence of compliance in the event of a claim.

BARRIER COATINGS

When transporting dirty or corrosive cargoes such as green delayed petcoke, calcined petcoke, coal, sulphur, and salt, a barrier coating can be applied to the hold steelwork. This coating forms a temporary barrier between the cargo and the hold structure. Manufacturers offer various hold coating options, such as slip-coat, slip coat plus, hold-block, or barrier coats, which protect the paintwork and are easier to remove than residues and cargo stains. Areas with broken-down paintwork, the tanktop, fixtures and fittings should be fully coated. It is important to follow the manufacturers’ instructions when applying and removing barrier coatings. Lime wash has traditionally been used as a barrier coating for corrosive cargoes like sulphur and salt. Follow the manufacturers’ instructions to ensure the proper application and removal of barrier coatings. The instructions will specify the quantity of lime used, and adding granulated sugar can facilitate the removal of the lime wash. Using intact paint coatings minimises the amount of lime wash needed. Once the barrier coating has been applied it should be allowed to dry thoroughly before loading begins.

POST CLEANING INSPECTIONS

Thorough inspections after hold cleaning are necessary to ensure compliance with regulations and provide evidence of cleanliness. Inspections should be conducted in well-lit conditions to identify any remaining residues or areas that require further cleaning. Proper lighting helps in capturing accurate documentation of hold conditions. Always maintain detailed documentation of hold inspections, including photographs or videos, to provide evidence of cleanliness. Record any findings or areas that may require follow-up cleaning. This documentation can be crucial in case of disputes or claims.

In the event of a delay between completing hold cleaning and loading, it is essential to periodically inspect the holds. This is because ship sweat can form, causing rust blisters to weep, and residues from previous cargoes may dislodge from their positions at the top of the hold and appear on the tank top. Regular checks will ensure that any potential issues are identified and addressed promptly.

PREVENTATIVE MEASURES

To protect their position and avoid disputes or claims, shipowners should consider the following:

- Conduct pre-loading inspections to ensure that the hold is clean and free from any residues or contaminants. This helps in identifying any potential issues before loading cargo.

- Maintain accurate records of hold cleaning activities, inspections, and any communication with charterers regarding hold cleanliness. These records can serve as evidence in case of disputes or claims.

- Maintain open and transparent communication with charterers regarding hold cleanliness. Inform them of the cleaning procedures followed, any issues identified during inspections, and any necessary remedial actions taken.

- Chartered entries should consider the differential in hold dimensions and hatch size when fixing a ship. The differential may mean that both a grab and bulldozer are required to discharge the cargo, considerably increasing discharge time.

- Remove as much cargo residue as possible at the discharge port, with local and MAPROL regulations always considered. This will better prepare shipowners in the event unforeseen circumstances, such as adverse weather.

- Local requirements may be more stringent than those typically experienced. Australia and the US are known to be areas with more strict requirements and shipowners should consult their local agents for up-to-date information on requirements in discharge ports.

Due to the large number of different bulk cargoes, the above is to be considered general advice. Always comply with the IMSBC Code and any Charterers’ instructions.

For further information, please do not hesitate to contact the loss prevention department.

English

English